Recycling Robots Startup is being Funded by Amazon

- Business

- March 7, 2024

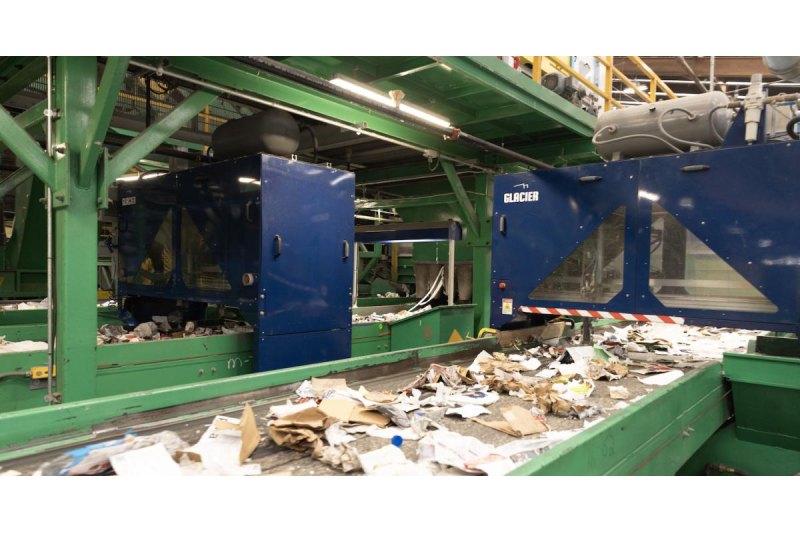

With $2 billion at launch, Amazon’s climate tech venture fund aims to support businesses creating viable answers to the company’s environmental sustainability and carbon reduction ambitions. It revealed support for its 25th project on Wednesday. Glacier is an early-stage, female-led San Francisco firm that creates cutting-edge, AI-guided recycling robots.

Among the major backers of Glacier’s $7.7 million round—which takes the company’s total funding to $13 million—are the Climate Pledge Fund and New Enterprise Associates. AlleyCorp, Overture Ventures, and VSC Ventures are among the other investors in this group. With Amazon’s involvement, the $53 million designated fund for its Female Founder Initiative has received its second investment.

As materials recovery facilities (MRFs) battle understaffing and the enormous number of unique materials — approximately 300 million tons in the U.S. alone in 2018 — that they are expected to treat, the market revenue for recycling robots is predicted to reach more than $10 billion by 2030.

“In order to build a future where new materials can be recycled at scale, we must test options to move these materials through the recycling system,” said Nick Ellis, principal of the Climate Pledge Fund. “Partnering with Glacier will enable us to test the role of novel AI and robotics-based recycling technologies so that we can identify and aggregate novel packaging materials that can ultimately be recycled and repurposed.”

Among The Distinctive Benefits Glacier Promotes Are:

- How reasonably priced its technology is. Although Glacier does not reveal prices, the co-founder said that facilities can see a return on investment in less than a year and that its robots are significantly less expensive than those of competing technology. Robots for recycling can cost as much as $300,000.

- Strong artificial intelligence software that can recognize over 30 different materials, from toothpaste tubes to aluminum cans; and Robots that can fit into small locations where other recycling robots cannot.

- The robots’ capacity to fit into small locations where other recycling robots are too large.

According to Ellis, Amazon is gathering information from a commercial pilot site at a metal recycling facility (MRF) in Northern California in order to figure out how to boost recycling recovery rates and identify items that can be sent back to manufacturers for use in meeting their waste reduction and circular economy goals.

These kinds of insights are what Glacier intends to offer to all parties involved in the recycling ecosystem, including product manufacturers, recycling facilities, and materials recovery firms. “Glacier is a wonderful example of how we can be a catalytic investor, a catalytic customer and a convener,” he stated.

Amazon’s Inclination For Industrial Equipment

The Climate Pledge Fund supports a number of industrial hardware companies, including Glacier. These three additional portfolio firms aim to challenge established procedures:

- CMC Packaging Automation creates the technologies that Amazon uses to customize cardboard boxes, eliminating waste and the need for single-use plastic cushions.

- The EV battery recycling company Redwood Materials is led by JB Straubel, a co-founder of Tesla.

- The 14-year-old European company Sunfire is creating green hydrogen electrolyzers, which may be used in Amazon’s fulfillment centers and other infrastructure.

According to Ellis, Amazon has not revealed the precise amount it is investing in Glacier or the amount of the Climate Pledge Fund that has been disbursed. The fund’s $1 billion investment in Rivian, an electric van manufacturer that produces over 100,000 cars for its delivery fleet, is its most well-known venture.

When It Makes Sense To Recycle Robots

Robots with artificial intelligence (AI) and other automation technologies are seen to be essential for MRFs to increase capacity and provide new revenue streams for selling gathered material back to producers who are keen to fulfill targets for using recycled content in their goods and packaging.

They function by visually identifying elements of the same type and separating them from waste streams using sensors and software intelligence. Aside from Glacier, AMP and TOMRA are two businesses hoping to be involved.

According to co-founder Rebecca Hu, Glacier plans to offer producers information that may be used to modify product design and packaging features in order to increase recycling rates, in addition to selling its technology to MRFs.

According to Glacier, up to 80% of household products that have the potential to be recycled are never incorporated into recycling programs. For instance, the anticipated yearly recovery rate for plastic in the United States is between 5 and 6 percent. Although a lot of businesses claim to be incorporating recycled content into their goods, the system isn’t processing enough material to satisfy demand in an economical manner.

Robots are being considered by recycling companies for locations “where it’s more difficult for sorters to perform the task” and “where it’s difficult to hire skilled workers,” according to Miriam Holsinger, co-president of Eureka Recycling, a nonprofit recycling company in Minneapolis.

Adoption of recycling robots has been hampered by costs, according to Holsinger, who cited the capital expenditure as well as other factors like the requirement to build auxiliary air compressors and provide personnel with the necessary maintenance training for the more sophisticated machinery. According to Holsinger, robots may also necessitate that MRFs redesign the layout of collection chutes and conveyors.

“That said, they show promise, especially where people aren’t able to handle the job,” she stated.