Cleaving Sapphire Wafers – Reducing Loss and Increasing Yield

- Guest Posts

- January 28, 2021

Cleaving is one of the swiftest methods where it is used in preparing materials of semiconductor and silicon. Sapphire is a material known for its single crystal material, but the cleaving process does not go well with it.

The methods that are existing are cleaving and sawing, but the yields are insufficient because of fractures that occur during the material loss during the processing period. Although methods like laser scribing and cryogenic cooling are known to minimize material loss, unwanted fractures, delamination, and chipping, but they are expensive and time-consuming. They can create problems like thermal damage, poor edge quality, and more.

Cleaving is considered the inexpensive and quickest method, that guarantees little to no material loss. This is guaranteed by the Latticegear, where it has developed two new cleaving methods. It needs its special cleaving tooland is different from handheld cleaving and scribing. It distinguishes itself from the other process as it involves new techniques. This method allows repeated process and eliminates the variation that takes place during the operational period. Besides, they also allow a new test, which is something not possible with the handheld process.

Let’s take a look at the two steps that are required to cleave.

- Step 1 – Weak Point Creation

It refers to the defect that is formed on the sample material. This weak point will be cleave’sstarting point. It is not possible to separate pieces without splitting a substrate. The weak point is created with the help of an indenter or diamond scriber.

The weak point on the sample edge will define the accuracy and quality of the cleave. The weak point, if made at an angle that is wide, deep, or not straight, then there are high chances that it will create fractures. In some cases, it will also create micro-fractures. This will affect the accuracy and quality of the surface that is cleaved and will affect it negatively.

- Cleaving

The next step to prepare a cleaved sample is cleaving. Stress is created on the weak point and then it is propagated and initiated on the sample. For instance, for the crystalline sample, the best weak point must be short as it helps to initiate cleave baking a crystal plane. This method will ensure a cross-section and will also present a mirror finish.

In the case of an amorphous sample, it will break without a crystal plane and will spread in the weak point direction. It will also not be straight unless a long scribe is made across the direction of the cleavage or the desired line. There will not be a mirror finish for the cross-section.

The point that is noted here is the crystal plane is counted to cleave and presents a rough edge. Cleaving can be done by splitting the samples into 2 pieces with pliers, fingers, or pins.

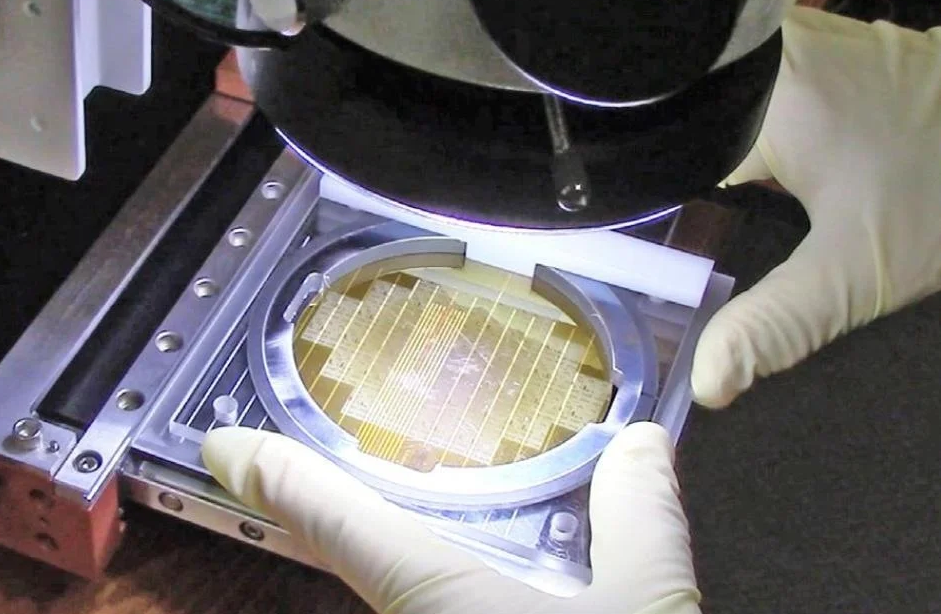

Cleaving a 3” Sapphire Wafer

Method 1 – Use of LatticeAx

The LatticeAx creates a cleaving and weak point production into one single tool. To create a weak point, a wedge-shaped diamond indenter is used. It takes the utmost five minutes to complete the process. It follows a crystal plane process and is based on the production of tools.

Method 2 – Use of Flipscribe

It is a tool to scribe the sample’s backside, while the operator works on the sample’s frontside. The samples are guided manually or with the aid of sample holders. This process shows that no matter how difficult the materials are, like in the case of sapphire, it can be cleaved effectively.

The preparation of LatticeAx presents a cleaved edge with a mirror finish, as it cleaves alongside the crystal plane. The Flipside does not come in contact with the frontside sample. While a clean break is defined and generated by the scribe line, which is aligned with the targeted surface.

It is believed that sapphire is one of the most difficult materials to cleave. But by using the right method and technique, it can be cleaved easily and smoothly. With the aid of a wafer cleaving tooland the right processes, the directions of the cleave can be controlled. The Flipscribe and LatticeAx are the prime additions when it comes to downsizing sapphire wafers for cross-section analysis and testing.